PRODUCTS

CLEANROOM CLEANLINESS MONITOR

Easy and flexible monitoring of cleanliness in cleanroom, etc.

Compact size

Connect to a computer

Easy measurement

Feature details

Free measurement of cleanroom contamination

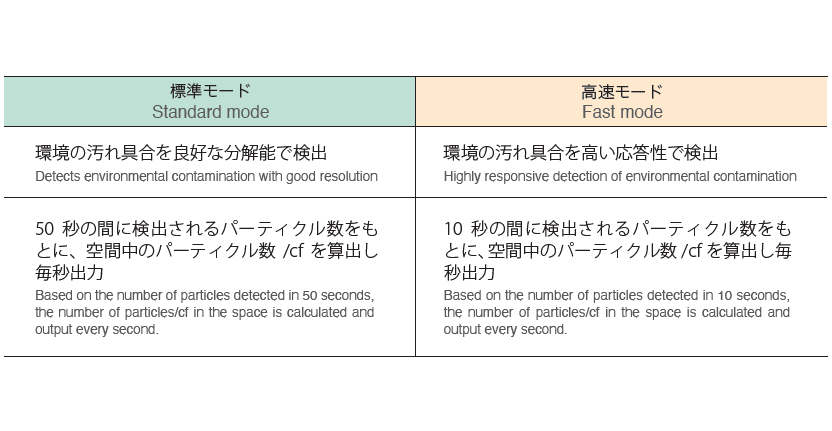

It can count the number of particles larger than 0.5μm or 2.5μm. Two measurement modes are available,

which can be selected according to the purpose.

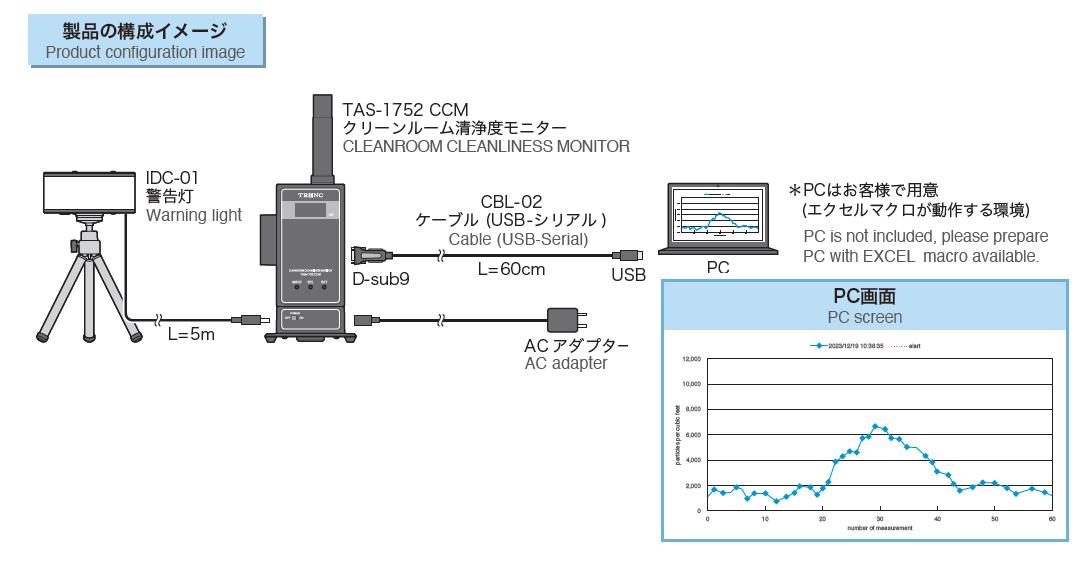

Data accumulation and graphing with PC connection

By connecting this unit to a PC, it is possible to graph cleanliness trends and manage data on the PC screen.

The standard software included is Excel-based, so anyone can easily handle the data.

Available for several purposes from in-situ measurement to long-term monitoring

This unit can be installed not only on a tabletop, but also at any desired position and height in a cleanroom by using the tripod provided, making it easy to measure cleanliness.

Combined with a PC, the high degree of freedom of installation and response performance enables on-the-spot tracking of cleanliness fluctuations, whether to analyze sudden changes in one second or to manage changes in cleanliness caused by production conditions or seasonal changes over a period of several months or a year.

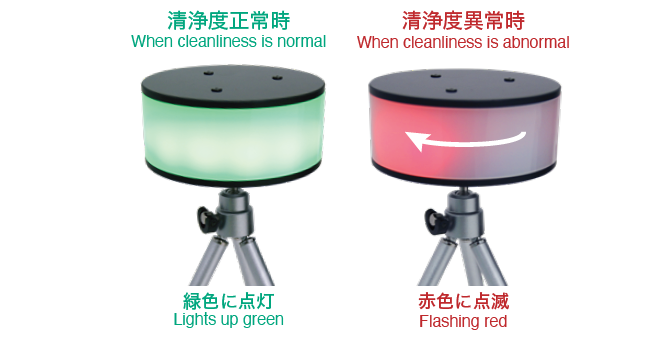

Notification by warning light when cleanliness is abnormal

By connecting with the warning light, it is possible to visually notify the surrounding area of a cleanliness abnormality the moment the set cleanliness level is exceeded. This allows workers in the area to immediately recognize the cleanliness abnormality, thereby preventing the production of defective products in advance. The threshold for issuing warnings can be freely set, allowing for flexible operation according to the site.

showers. Particle counters are used to monitor cleanliness in factories where particularly high cleanliness is required, and to determine the cause of foreign

matter defects when they occur. Particle counters are designed to measure according to ISO standards for cleanroom grades, so while they have high

measurement performance, they take time to measure and tend to be large and expensive.

In contrast, there is a need to be able to easily and freely determine whether the environment in the factory is clean or contaminated at any given location at

the actual manufacturing site, and TRINC has developed a new environmental evaluation device, the CLEANROOM CLEANLINESS MONITOR, to meet this

need.