PRODUCTS

NON-CONTACT SPOT CLEANER

Non-contact and powerful dust removal and collection from a targeted spot

Powerful dust removal and collection

No sucking up the workpieces

Equipped with a powerful ionizer

Feature details

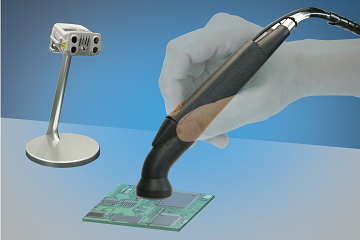

Non-contact pen-type spot cleaner based on a new principle

This is a local cleaner based on a new principle that removes adhered foreign matter without touching the workpiece. Since it is a completely non-contact cleaning system, there is no risk of damaging or contaminating even fragile and delicate work surfaces. It is possible to locally clean only the targeted area with minimal impact on the surrounding area.

Simply hold the tip of the cleaning head over the spot to be cleaned and press the button once with your finger to instantly complete the cleaning process. It has a slim stick shape with a diameter of 26mm and weighs only 33g. Since it can be held as if holding a pen, the spot to be targeted can be cleaned precisely without stress with a good field of view.

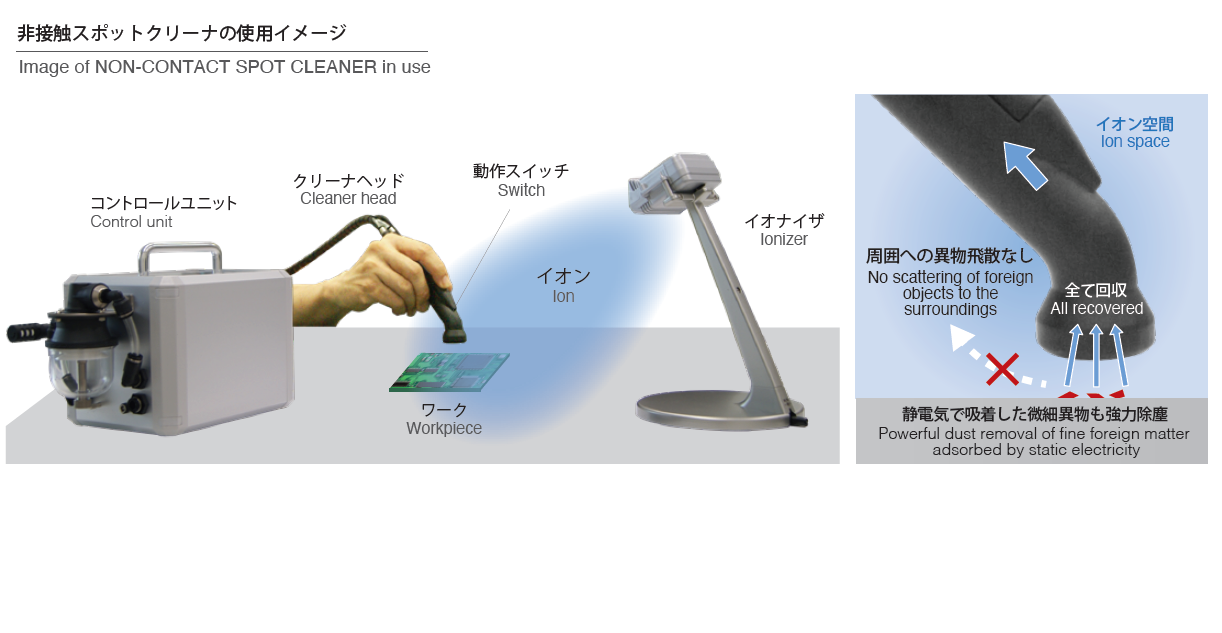

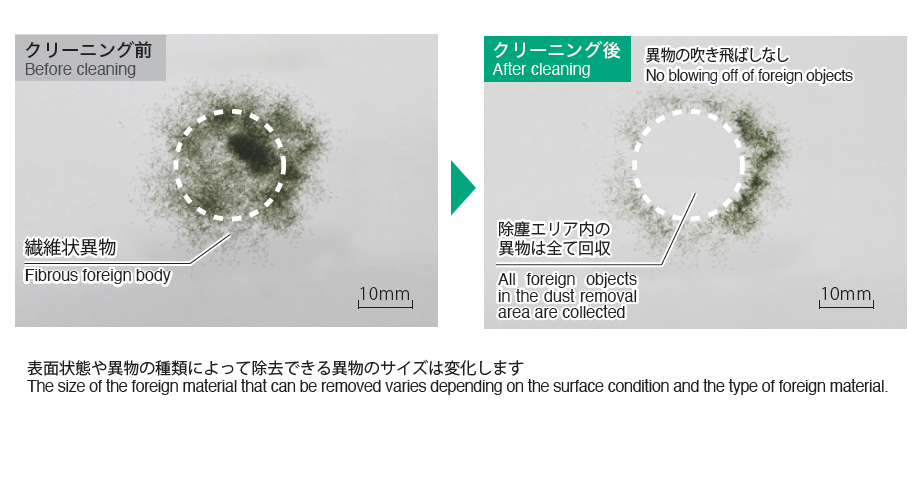

Non-contact, powerful dust removal and collection

The adoption of a unique dust removal principle makes it possible to remove foreign matter more powerfully than conventional air blowers or vacuum suction. In particular, it is difficult to remove minute particles attached by static electricity, but this machine removes even particles as small as 10μm, leaving no residue. Furthermore, since all removed particles are collected without scattering them around the environment, there is no risk of them flying around the environment and causing other foreign matter defects.

Collects only foreign matter without sucking up the workpiece

Despite its powerful foreign matter removal and recovery capability, the machine can efficiently collect only foreign matter without sucking up the workpiece. This means that even when cleaning thin, flexible or lightweight workpieces such as film or sheet, there is no risk of the workpiece being sucked up and rolled in.

Powerful ionizer (electrostatic eliminator) for improved dust removal

The included high-performance ionizer fills the dust removal area with ions, effectively removing even fine foreign matter that is firmly attached by static electricity. It can also be used to prevent static electricity on workpieces.

Energy-saving operation with instantaneous cleaning

When the operation switch is pressed, cleaning is completed about one second. Therefore, air consumption is negligible. In addition, the included ionizer is a no-air type ionizer and consumes only 10W of power.

Collected foreign objects can be easily disposed of

The removed foreign matter is collected in a collection bottle attached to the Control unit. This bottle can be easily removed without the need for tools and can be disposed of at any time.

At the manufacturing sites of precision instruments and optical devices, efforts are made to take measures against foreign matter in order to ensure the performance and reliability of products. In the assembly and inspection processes of optical elements, high-function films, electronic substrates, etc., workers carefully check products and parts for foreign matter, and if foreign matter is found adhering there, it is thoroughly and promptly removed.

Methods for pinpoint removal of locally adhered foreign matter can be classified into two types: contact and non-contact. In contact-type foreign matter removal, the worker directly grabs the foreign matter with tweezers and removes it, or a viscous cotton swab is used to absorb the foreign matter and remove it. These methods are highly versatile because they do not require special equipment. However, as products become more sophisticated, the size of foreign matter that must be removed is becoming smaller every year, making it increasingly difficult to handle these methods by hand. In more than a few cases, contact may cause damage to the product, in which case the foreign matter must be removed in a non-contact manner.

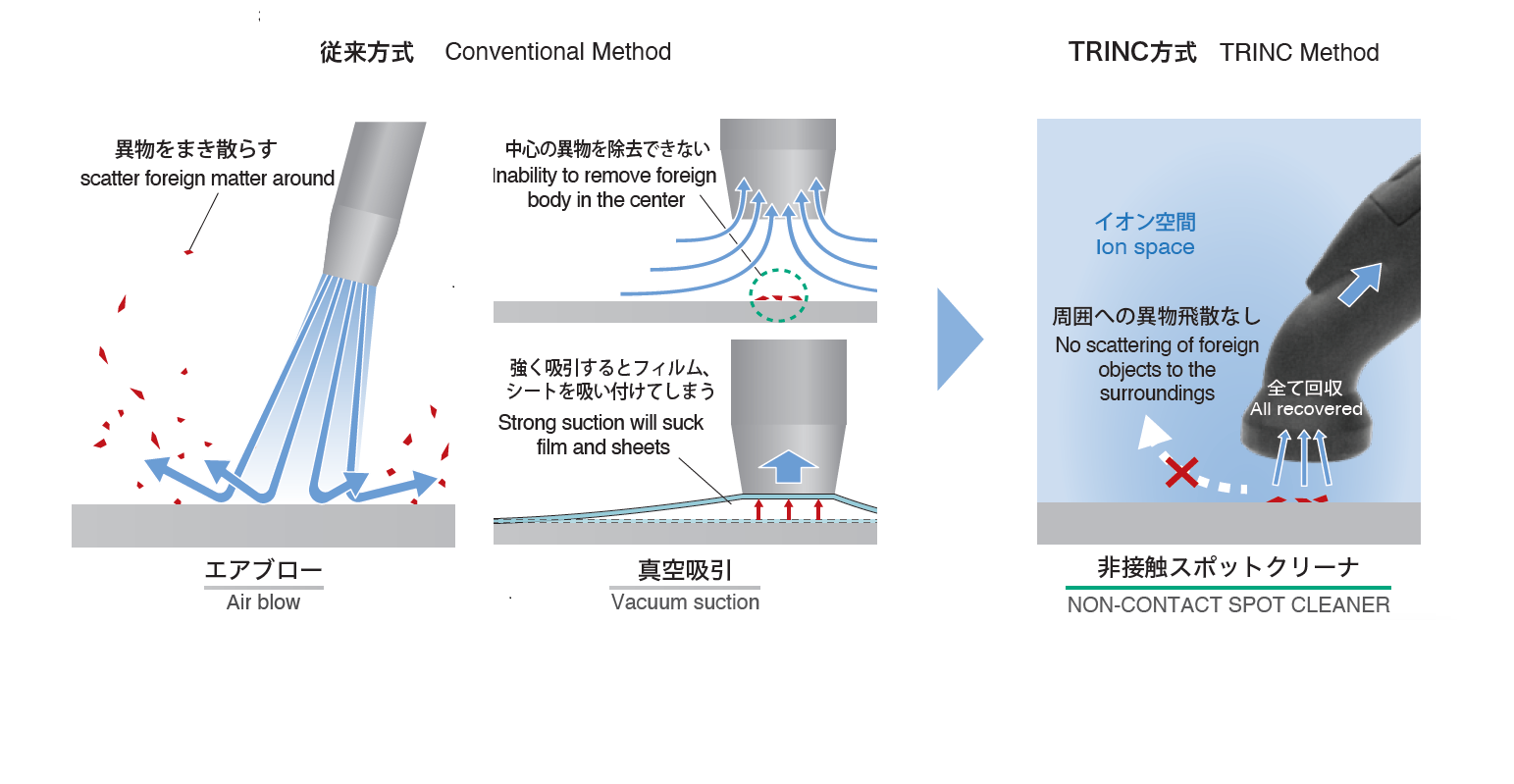

Methods for non-contact, localized removal of foreign matter include blowing them away with an air blower or vacuuming them with a thin nozzle. However, simply blowing foreign matter with air is not desirable in a clean work environment because the paid foreign matter will contaminate the environment. In addition, air blowing alone cannot remove fine particles that are firmly adsorbed by static electricity. On the other hand, vacuum suction cannot effectively remove fine particles because its ability to remove them is significantly reduced in the same way. If the pressure is then increased to create a strong suction, the workpiece may be sucked into the vacuum and damaged.

As described above, there has been no ideal means to remove fine particles from workpieces in the past. TRINC's "Non-Contact Spot Cleaner" was developed to break through this situation. This is a spot cleaner based on a new principle that can instantaneously remove minute adhering foreign matter from a targeted spot with no contact, and quickly collect it on the spot.

TRINC's "Non-Contact Spot Cleaner" has a pen shape that is ideal for use in the operator's hand. This extremely compact and lightweight handheld cleaner fits comfortably in the operator's hand and can target and securely remove adhered foreign matter.

The unique air control structure based on a new principle ensures efficient removal and collection of foreign matter. It should be noted that while the TRINC has a high foreign material recovery capacity, it does not suck in workpieces, so even fragile workpieces can be cleaned safely and powerfully. In addition, TRINC's powerful ionizer removes foreign matter while filling the targeted spot with ions, which is highly effective in removing foreign matter that is firmly attached due to static electricity. This powerful ionizer removes minute particles that could not be removed by conventional methods, without touching the parts.

Furthermore, all removed foreign matter can be immediately recovered, eliminating the risk of contaminating the environment and causing other foreign matter problems. In other words, the ideal countermeasure, which was impossible in the past, becomes possible and leads to the solution of the problem.