PRODUCTS

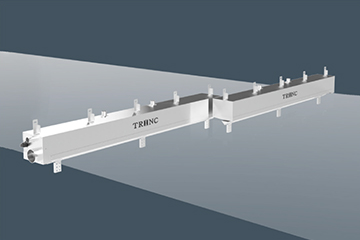

PANEL TRINC

TAS-1474 PANELG-790

TAS-1475 PANELG-1590

TAS-1476 PANELG-3000

The panel cleaner with a new principle featuring;

“High performance””Low cost””Retrofitable”comes on stage.

Low price

High dust-removing performance

Perfectly non-contact processing

Low power consumption

Compact size & light weight

Feature details

High dust removal rate

With a new dust removal principle developed, the dust-removal rate remained conventionally at about 10% has been improved up to 99% (actually measured value).

Uniform performance in the entire region

A uniform dust-removal rate over the entire glass panel surface has been realized.

Stable performance

Without being affected by the precision required mechanically and the environment of work site, the stable performance is demonstrated.

Compact and light-weight

Because it does not require the precise mechanism such as back-up rollers, it is made smaller and lighter.

Possible add on to existing facilities

By now a small, it is possible without modifying the existing facility built-in if there is a small empty space.

Improved profitability with low cost

Because the conventional panel cleaner is so expensive, people couldn’t use it at ease when it comes to the profitability. This device is made as cheap as the cost of a several parts of the conventional devices, making it so much easy to be profitable. At the various machining processes and the inspection and packing processes as well that have lowered the production yield in the past, it becomes possible to increase drastically the productivity and quality by cleaning products beforehand.