SOLUTION

Automobiles

85% reduction in paint failures in automotive bumper paint shops

Case study in a bumper painting line of an automobile manufacturer

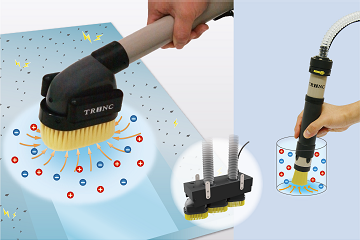

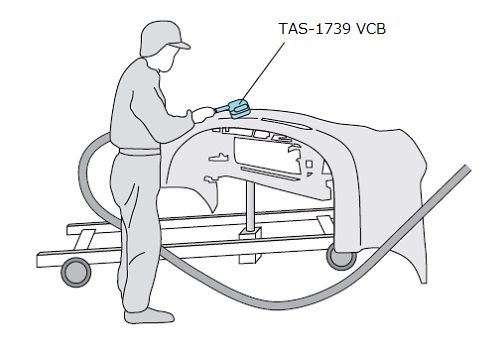

| At an automobile bumper coating plant of a major automobile manufacturer, dust removal was being performed using an ionizing gun in order to reduce defects. In order to adopt a static eliminating gun that could remove more foreign matter, they evaluated various manufacturers’ static eliminating guns in the pre-coating process, but were dissatisfied because the coating defects were not eliminated as expected. At such time, they tried TRINC’s GUN TRINC (TAS-21 GCB) and found that it had a powerful static eliminating effect and greatly reduced foreign matter defects. However, the person on site, who was aware of the disadvantages of blowing off foreign substances with air, was ambitious to further improve the process, and decided to use a brush to remove foreign substances from the product instead of blowing them off. They conducted an evaluation using VACUUM TRINCs (TAS-1739 VCB ), which do not blow off foreign matter attached to products, but scrape it off with a brush and suction it with a vacuum. |

|

The VACUUM TRINC did not leak the removed foreign matter to the outside, and even some sticky foreign matter was powerfully scrubbed away, resulting in an 85% reduction in coating defects.