SOLUTION

Optical/precision equipment

Dust-related complaints reduced to “zero” at medical copier assembly plant

Case study at a copier/multifunction device manufacturer

| A multifunction printer manufacturer’s medical copier manufacturing plant had to pay close attention to foreign matter because even the slightest dust on their products would cause complaints from the hospitals that are their customers. Since these copiers are used for diagnosis, if dust adheres to the copier and print quality deteriorates, it could cause a serious error, which could be misidentified as a lesion, so users were very sensitive to foreign matter. No matter how much improvement efforts were made to prevent foreign matter from adhering to the products, the hospital to which the products were delivered inevitably received about five complaints every month. |  |

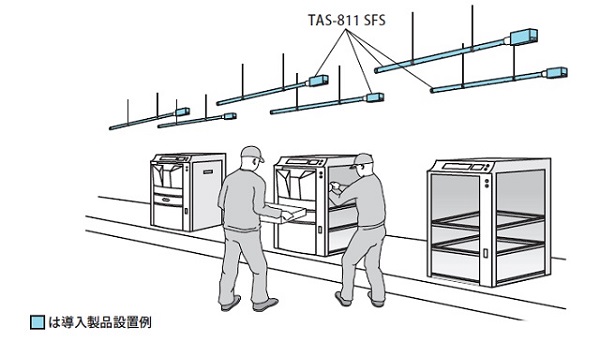

Realizing the limitations of conventional countermeasures, the plant found a new way to prevent foreign matter from adhering to the products: the use of space ionizing to prevent dust adhesion in the space. First, on a trial basis, a STATIC-FREE SPACE TRINC (TAS-821 SFS) was installed throughout one assembly line. The line was then completely free of dust, and zero dust-related complaints were achieved. In addition to the elimination of foreign matter adhesion, the dust that had been difficult to remove even after repeated blows was now easily removed, making the work overwhelmingly easier and eradicating foreign matter adhesion.

The workability improvement was also greatly appreciated in that it eliminated the need for conventional wrist straps. Currently, similar measures are being implemented on other lines and in other plants.

The workability improvement was also greatly appreciated in that it eliminated the need for conventional wrist straps. Currently, similar measures are being implemented on other lines and in other plants.