SOLUTION

Medical/Food/Daily Necessities

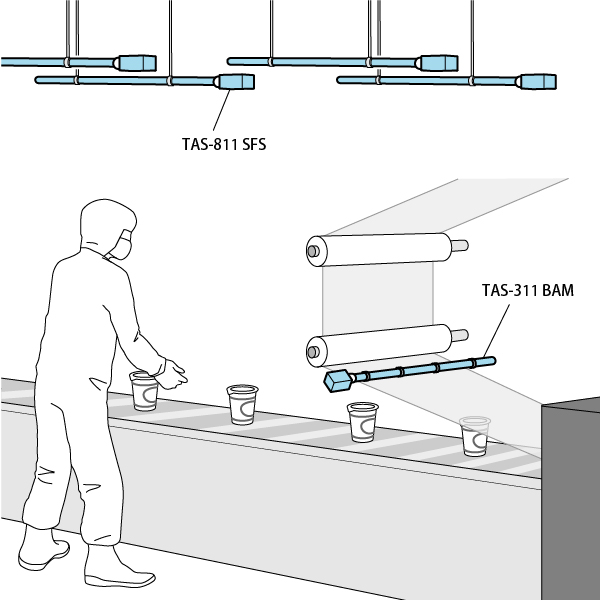

Zero claims of foreign material contamination in shrink-wrapped cup noodles

Case study of a food manufacturer’s cup noodle manufacturing plant

| A major food manufacturer received several complaints each month about hair contamination in the shrink-wrapping of cup noodles, and it was urgent to take countermeasures. The company evaluated the effectiveness of space ionizing in preventing hair contamination in the shrink-wrapping process at a cup noodle manufacturing plant. After installing STATIC-FREE SPACE TRINC (TAS-811 SFS) on only one line out of several lines and testing it for three months, the number of market complaints was reduced to zero. On the other hand, other lines that were not equipped with STATIC-FREE SPACE TRINC still had the same complaints. |

|

Upon investigation, it was confirmed that on the line where the STATIC-FREE SPACE TRINC was installed, there was a clear increase in the number of hairs falling to the floor during cleaning. It is thought that the hair, which used to be attracted to products and workers by static electricity and adhered to them, fell directly to the floor due to the space ionizing effect, preventing market complaints.

Based on these results, the company is taking on the challenge of eliminating claims of foreign matter by horizontally deploying this measure to other lines and factories.

Based on these results, the company is taking on the challenge of eliminating claims of foreign matter by horizontally deploying this measure to other lines and factories.