SOLUTION

Electronics

Foreign dust adhering reduced 99% to processing printed circuit boards

Case study of a printed circuit board manufacturer’s factory in China

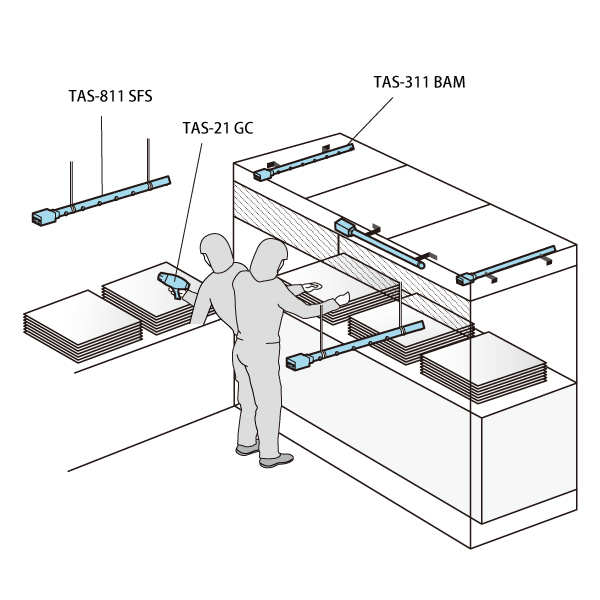

| In the PCB machining process of a global manufacturer of printed circuit boards, foreign matter defects caused by particles floating in the environment, dust emitted by workers, and dust generated during PCB processing had become a problem. When STATIC-FREE SPACE TRINC was installed to prevent this problem, it was extremely effective in preventing dust adhesion. STATIC-FREE SPACE TRINC can remove static electricity from all objects present in the space by filling the work area with ions (Space ionizing). Notably, it can simultaneously neutralize the static electricity of not only the product but also foreign matter floating in the space, preventing foreign matter adhesion by canceling the Coulomb attraction caused by the static electricity acting between the two. In an area where a particularly remarkable effect was achieved, foreign matter adhesion was reduced from 230,000 pieces to 15,000 pieces, resulting in a 99% reduction in foreign matter adhesion. |

|