SOLUTION

Electronics

75% reduction of foreign matter defects in display manufacturing plants

Example in a FPD manufacturing plant

| At a flat panel display (FPD) manufacturing plant, foreign matter was adhering to products in the process of unpacking glass substrates and feeding them into the manufacturing line, and in the process of transferring products from one manufacturing facility to the next, causing yield deterioration. In order to prevent foreign matter from adhering to the products during these processes, the plant had surrounded the production line with transparent acrylic panels to prevent foreign matter from entering the work space from the outside. However, even with these measures, foreign matter defects could not be avoided. No matter how much we tried to eliminate foreign matter by separating the space, foreign matter inflow and dust generation could not be avoided at the actual manufacturing site, where things move in and out, and are assembled and processed. |

|

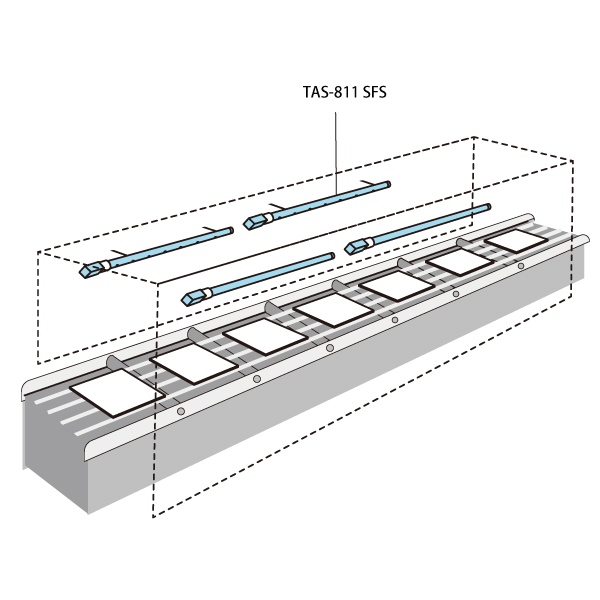

The plant determined that no further improvement could be expected, no matter how many conventional countermeasures were pursued, and decided to adopt a new countermeasure against foreign matter and static electricity: the use of space static elimination to prevent dust in the space. By introducing STATIC-FREE SPACE TRINC (TAS-811 SFS, TAS-821 SFS) inside the installed acrylic covers and neutralizing static electricity from glass substrates and floating foreign matter, the number of foreign matter defects was dramatically reduced by 75% the day after STATIC-FREE SPACE TRINC were installed.