SOLUTION

Automobiles

Dust adhesion rate is reduced in 74%, at process before car painting.

Case study in an automotive manufacturer’s paint line

| At major automobile manufacturers, the car bodies are polished to create a beautiful surface just prior to body painting. This process creates the perfect surface of the car body, and then no foreign matter (dust) is allowed to adhere to the body until the painting process is completed. When dust from the polishing process or foreign matter floating in the environment adhered to the body, it was removed by wiping it off with a rag or rubbing it with a rotating feather, but these methods did not effectively remove foreign matter attached by static electricity, leading to poor painting. |

|

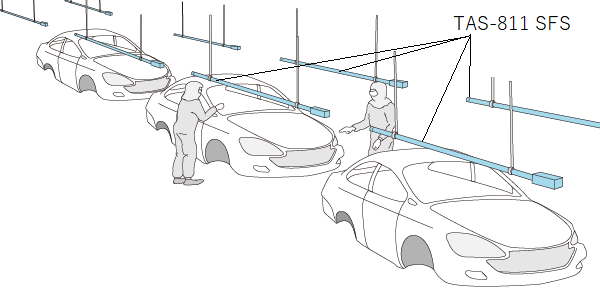

The plant adopted a countermeasure to prevent foreign matter from adhering by means of STATIC-FREE SPACE TRINC. They were installed at the top of the line along which automobile bodies were transported. The work area was then filled with ions, which constantly neutralized the static electricity generated by the foreign matter floating in the environment and the powder generated by polishing, dramatically reducing the amount of adhesion. When the effect was confirmed, the amount of foreign matter adhesion was reduced by 74%. In addition, the electrostatic attraction between the foreign matter and the car body was reduced to an absolute minimum, so that even if the foreign matter was stuck to the surface, it could be easily removed. This has resulted in a significant reduction in final paint defects.