SOLUTION

Automobiles

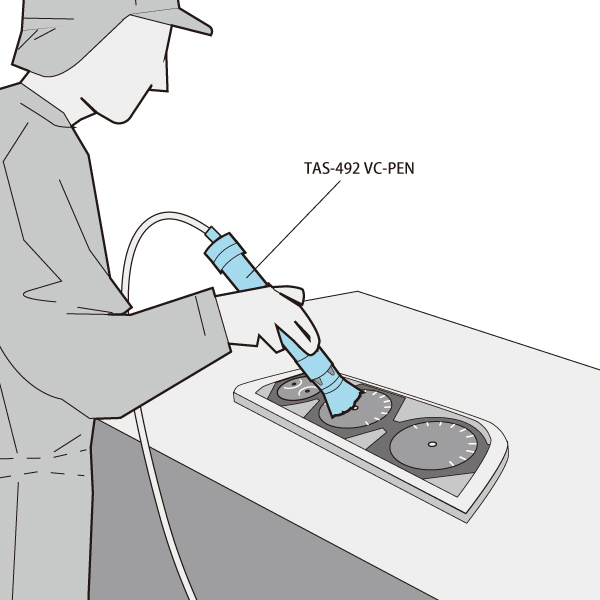

Dust defects reduced 74%, in speedmeters product process.

Case study of an automotive instrument manufacturer

|

Automobile meter manufacturing plants are required to take thorough measures against foreign matter. Foreign matter in instrument displays, which are actively checked by the eyes when driving, is a serious problem. For this reason, we carefully remove dust from each part, especially during assembly.

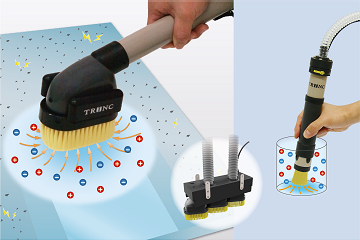

At a plant where VACUUM TRINC PENs were used in the static elimination and dust removal process for speedometers, a 72.6% reduction rate was achieved for in-process foreign matter defects, and a 74.7% reduction rate for fiber waste defects. VACUUM TRINC PEN collects foreign matter adhering to parts by scraping it off with a brush, and during this process, the dense ions continue to powerfully ionize the dust-removing area, resulting in a high dust removal capability that cannot be achieved using other methods. |

|

When they presented this great effect that exceeded their expectations within the company, the audience was in an uproar. As a result, the great improvement effect was highly evaluated, and the VACUUM TRINC (VC-PEN) series is continuously used as a standard tool all over the world, including factories in Europe and other countries.