SOLUTION

Optical/precision equipment

75% reduction in foreign matter adhesion during high-performance lens storage

Case study of a precision equipment manufacturer involved in cameras and semiconductor equipment

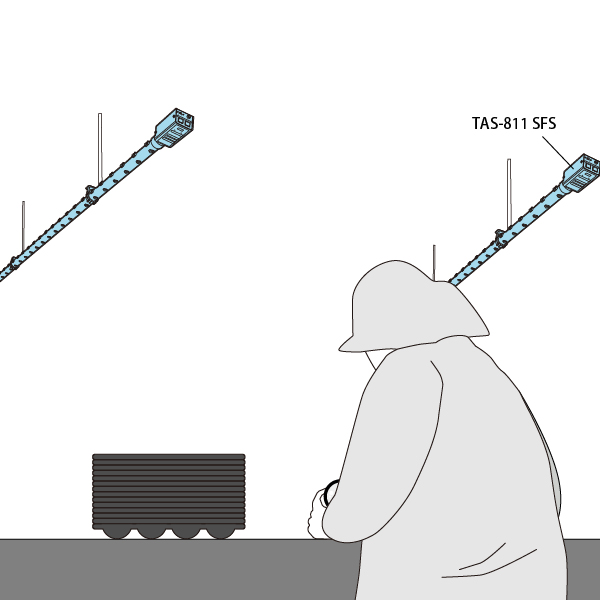

| STATIC-FREE SPACE TRINC (TAS-811 SFS) is contributing to foreign matter control at a major camera manufacturer’s lens manufacturing plant. The use of STATIC-FREE SPACE TRINC has drastically reduced foreign matter adherence to lenses during storage, assembly, and inspection, and it is widely used in various phases due to its high effectiveness and reliability, from development and prototype lines to production plants. STATIC-FREE SPACE TRINC is an unparalleled and unique device that can make a work area an ionized space with no airflow (Space ionizing). In the past, humidification was used as an anti-static measure, but there was a risk of fogging of optical elements due to condensation, and the running cost was not commensurate with the static electricity removal capability. |

|

In contrast, STATIC-FREE SPACE TRINC can strongly neutralize static electricity even in dry conditions. The static elimination target includes not only products but also dust floating in the air. By neutralizing static electricity from both the product and the dust, the attraction and adsorption of foreign matter due to Coulomb attraction is suppressed and foreign matter adhesion is prevented. This effect, which prevents foreign matter from adhering to products based on a different principle than in a cleanroom is one of the major effects of space ionization by STATIC-FREE SPACE TRINC.

The actual effectiveness of preventing foreign matter adhesion in the lens storage process is 75%, and due to its high effectiveness, it is being adopted not only in the lens storage process, but also in the assembly and inspection processes.

The actual effectiveness of preventing foreign matter adhesion in the lens storage process is 75%, and due to its high effectiveness, it is being adopted not only in the lens storage process, but also in the assembly and inspection processes.