SOLUTION

Optical/precision equipment

300% increase in after-sales service efficiency for SLR cameras

Case study at a camera manufacturer’s service center

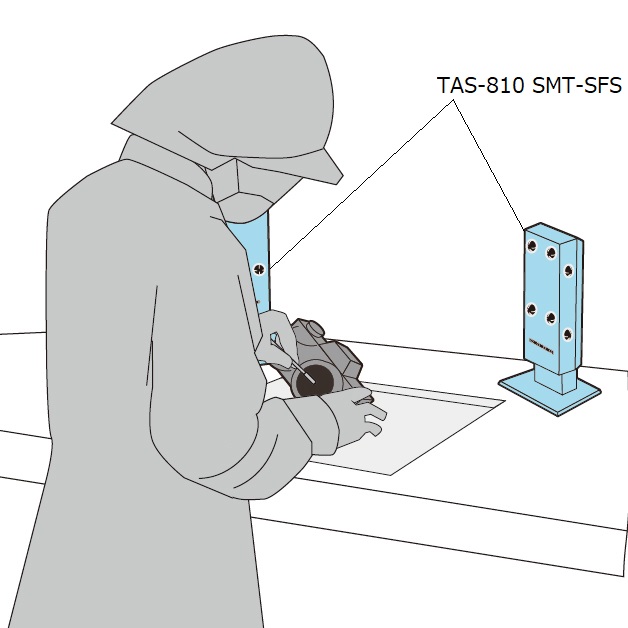

| Major camera manufacturers have service centers throughout Japan that perform maintenance on SLR cameras after purchase. Every day, many equipment is brought to these centers to have the camera body and lenses cleaned, which is difficult for users who have purchased the camera themselves. However, because no anti-static measures were taken to prevent foreign objects from adhering to the camera, the foreign objects could not be removed, and even if they were removed, other foreign objects would reattach to the camera. The problem was that even if they were removed, other foreign matter would re-deposit. |

|

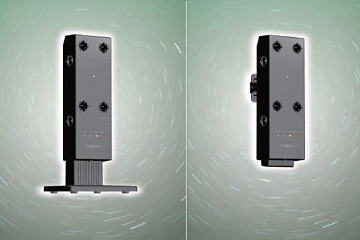

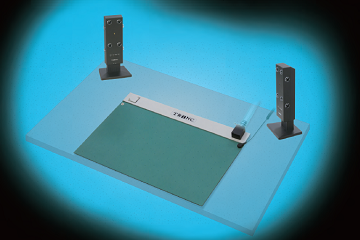

The company introduced the STATIC-FREE SPACE SMART TRINC (TAS-810 SMT-SFS) and ZERO-ZERO KIT TRINC (TAS-612 ZERO) at the work site. As a result, the work time was reduced from 1 to 2 hours per unit to 30 minutes, and work efficiency was improved by 100 to 300%.

The customer was very pleased with the results, which not only enabled a reduction in the number of workers, but also had a great effect in promoting the company’s quick and high cleaning technology to customers.