SOLUTION

Chemistry/Materials

75% reduction of foreign matter adhesion during storage of functional films

Example at an electronics film manufacturing plant

| At an electronics film manufacturing plant, foreign matter products adhering to film during storage after rewinding was a problem. The film rolls were stored on racks in a cleanroom, but it was impossible to avoid foreign matter adhesion due to the large amount of dust and foreign matter brought in and out of the racks by people and materials during loading and unloading. A fan-type static eliminator had been installed to prevent static electricity, but the air-assisted static eliminator was counterproductive as a countermeasure against foreign substances, because it would wind up foreign substances and disrupt the airflow in the cleanroom, making the situation even worse. |

|

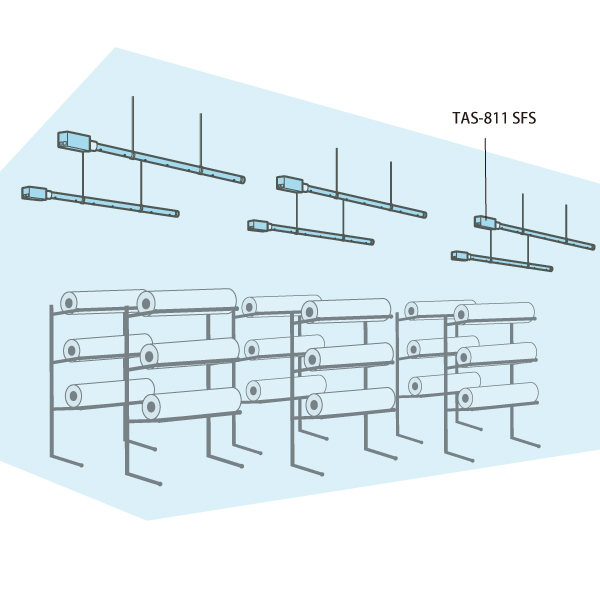

The decision was made to remove the air-assisted static eliminator, which was causing problems, and switch to no-blow space-type static eliminator, which can eliminate static throughout the entire space without airflow. Four sets of STATIC-FREE SPACE TRINC (TAS-811 SFS) were installed on top of the film roll racks in the cleanroom to prevent foreign matter from adhering to the rolls by taking advantage of the space ionizing. As a result, while more than 20 foreign objects adhered to the film rolls after 2 hours of standing when an air-assist type static eliminator was used, the use of STATIC-FREE SPACE TRINC made it possible to reduce the number of foreign objects to 5 or less even after 2 hours of standing.

The 75% drastic reduction in foreign matter adhesion revealed that the air-assisted ionizers had become harmful in the cleanroom. They have introduced additional devices, and are working to achieve zero foreign material defect.

The 75% drastic reduction in foreign matter adhesion revealed that the air-assisted ionizers had become harmful in the cleanroom. They have introduced additional devices, and are working to achieve zero foreign material defect.