SOLUTION

Optical/precision equipment

Solves static electricity problems in industrial printers and improves print quality

Case study in a manufacturer that develops and produces large inkjet printers, cutting machines, and 3D printers

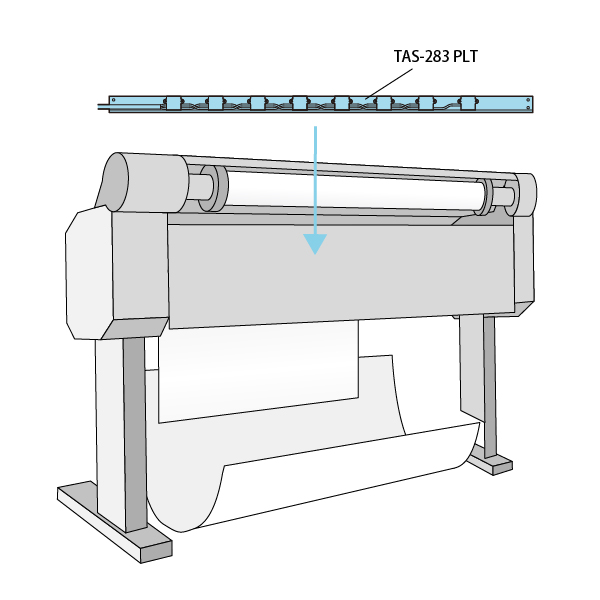

| PLATE BAR TRINC is used to prevent static electricity in industrial inkjet printers. Static electricity between the inkjet printer and the substrate can prevent ink droplets from flying to the target point, making high-definition printing difficult. This is especially true with UV inkjet printers, where the printed material is often made of materials that are prone to static electricity. To ensure the quality of UV inkjet printing, the printer manufacturer introduced in this case study has adopted PLATE BAR TRINC in the printer head. Since this ionizer has an extremely thin plate-like shape, it can be installed in a small gap inside the printer head to solve the static electricity problem during printing. |

|

The engineer who promoted the adoption of the PLATE BAR TRINC was very pleased to hear from the sales representative in Japan that the customer’s evaluation was very positive after the introduction of the device. Although evaluations had already been conducted at the experimental level, the printer was so well received by customers who actually used it that the engineer was enthusiastic about expanding the use of the device not only in Japan but also in products for overseas markets and rolling it out worldwide.