SOLUTION

Automobiles

Dramatic reduction of foreign matter adhesion during storage of molded products

Case study of an automotive interior and exterior parts manufacturing plant

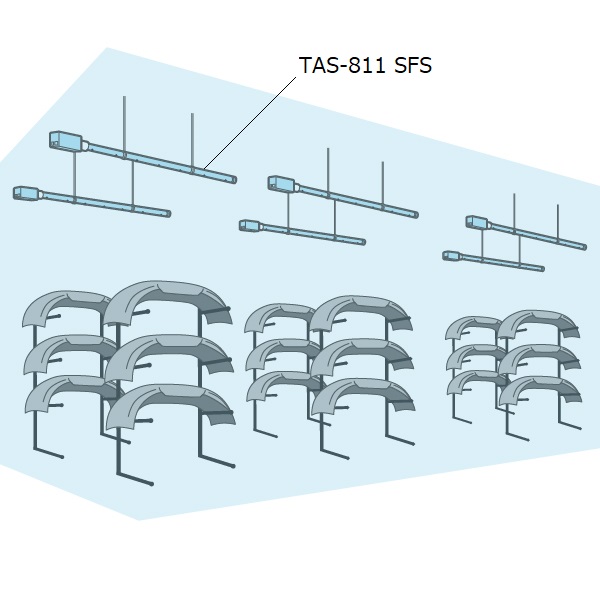

| At a bumper and grille production plant of an automotive interior and exterior parts manufacturer, STATIC-FREE SPACE TRINC (TAS-811 SFS) are used to prevent foreign matter during the inspection and storage process before the painting booth. Molded products are strongly charged with static electricity immediately after molding, which attracts floating foreign matter from the surrounding environment. By storing molded products together in a space ionized atmosphere, this static charge can be eliminated. When measuring static electricity, a surface potential of 15 kV was observed immediately after molding, but when the products were sent to a storage space where spatial ionization by STATIC-FREE SPACE TRINC was functioning, the static electricity was eliminated to almost 0 V, which was maintained permanently. |

|

Because STATIC-FREE SPACE TRINC continues to neutralize static electricity from foreign matter floating in the environment at the same time as the product, static electricity from the molded product and the foreign matter can be kept at zero at all times. This greatly reduces the risk of foreign matter adhering to the product. In fact, there is a clear visual difference in the degree of foreign matter adhesion between products stored in an area with STATIC-FREE SPACE TRINC and those stored in an area without them.

STATIC-FREE SPACE TRINC not only suppresses foreign matter adhesion, but even if foreign matter does adhere, it weakens the force of static electricity, making it easier to remove.

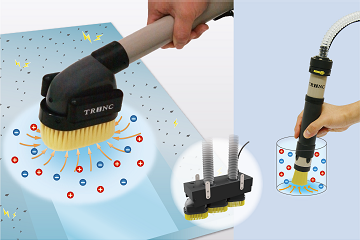

In this factory, foreign matter is removed in the pre-painting process using GUN TRINC and VACUUM TRINC in an

environment where the STATIC-FREE SPACE TRINC is installed, and all possible measures against static electricity and foreign matter have been introduced throughout the process from molding to painting.

STATIC-FREE SPACE TRINC not only suppresses foreign matter adhesion, but even if foreign matter does adhere, it weakens the force of static electricity, making it easier to remove.

In this factory, foreign matter is removed in the pre-painting process using GUN TRINC and VACUUM TRINC in an

environment where the STATIC-FREE SPACE TRINC is installed, and all possible measures against static electricity and foreign matter have been introduced throughout the process from molding to painting.