SOLUTION

Chemistry/Materials

Foreign matter adhesion to functional films is reduced to 0 in inspection process

Case study of a highly-functional film manufacturing and processing plant for automotive and electronics applications

| At functional film manufacturing plants, products are visually inspected to ensure that there are no abnormalities before packaging and wrapping. However, because film is a material that easily becomes charged with static electricity, new foreign matter is attracted to the film and adheres to it during the inspection process, making the inspection inefficient. |

.png) |

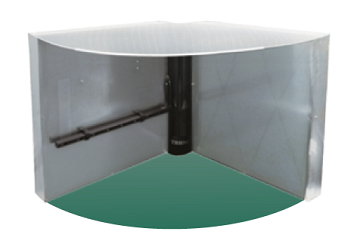

They introduced the CLEAN DESKTOP TRINC (CDT) to review the countermeasures against foreign matter and static electricity in the workspace, which can remove floating foreign matter from the work area with high purification capacity and prevent dust generated by workers from entering the interior, thus maintaining a Class 1 ultra-clean space inside.In addition, the CDT can instantly remove static electricity from materials in the space, thus thoroughly preventing foreign matter from adhering to the interior.

With the introduction of the CDT, foreign matter adhesion is completely eliminated during inspections, which has resulted in a significant reduction in inspection time.

With the introduction of the CDT, foreign matter adhesion is completely eliminated during inspections, which has resulted in a significant reduction in inspection time.