SOLUTION

Medical/Food/Daily Necessities

Catheter assembly process rework reduced by 30%

Case study at a specialty medical device manufacturer

| Catheters, which are medical devices, can cause serious problems if foreign substances adhere to them due to the nature of the product. Therefore, catheter manufacturing plants take the utmost care to prevent foreign substances from adhering to catheters. In reality, however, even if work is done in a cleanroom, foreign matter adhesion was inevitable in catheter production lines where catheters are often assembled by hand. |

|

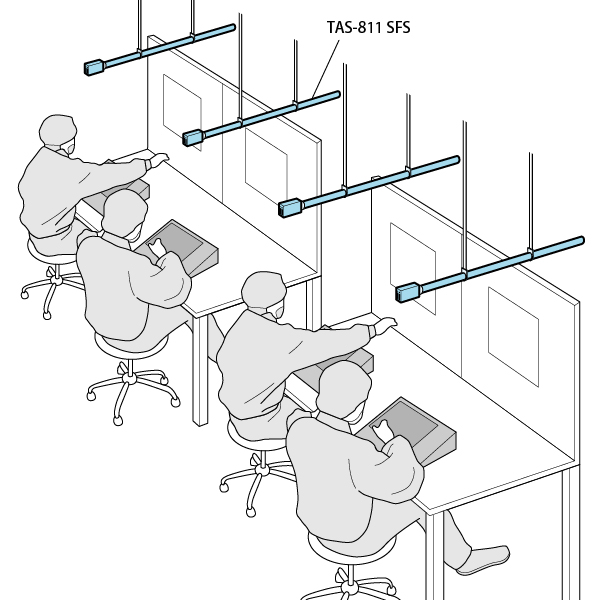

As a new measure to avoid foreign matter adhesion, STATIC-FREE SPACE TRINC (TAS-811 SFS) were introduced to the catheter assembly line. The dust-adhesion prevention effect of the STATIC-FREE SPACE TRINC reduced foreign matter adhesion in the assembly process, resulting in a 30% reduction in rework after inspections.

This significant improvement led to the decision to expand the countermeasure horizontally to other guidewire production lines in addition to the catheter assembly process.

This significant improvement led to the decision to expand the countermeasure horizontally to other guidewire production lines in addition to the catheter assembly process.