SOLUTION

Medical/Food/Daily Necessities

Improved level of foreign material control in bio-cleanrooms

Case study of a chemical company’s biotech R&D center

|

In a bioclean room, there is a risk of viruses and bacteria spreading infection via foreign matter, so thorough control and countermeasures against foreign matter are essential. In the actual operation of a bioclean room at a major chemical manufacturer, additional measures were needed because the foreign matter problem could not be solved no matter how thoroughly the facility was managed.

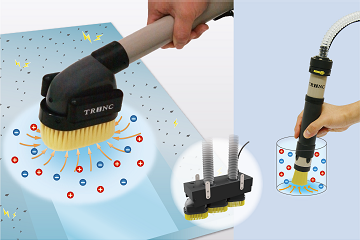

They installed STATIC-FREE SPACE TRINC (TAS-811) and VACUUM TRINC (TAS-1739) to prevent foreign matter from adhering to personnel, products, and equipment and to remove dust from incoming materials. |

|

After the installation, they measured the effect of the VACUUM TRINC and found that not only did they have a significant effect on particles larger than 300 μm, of which measures are required especially, but they also reduced the number of particles smaller than 100 μm, resulting in a significant improvement beyond expectations. The company has said that the problems that could not be solved in the past cleanroom operations, even after reviewing operations and improving cleaning, have been resolved, and that they now recognize that TRINC products are indispensable for achieving their quality targets.

In the future, they plan to introduce other countermeasure equipment, such as ion air showers and cleanroom units, to implement an even higher level of foreign material control.