SOLUTION

Electronics

Switch from wet cleaning to TRINC method to save energy and manpower

Case study of a quartz crystal device manufacturing plant

| Factories that manufacture quartz crystal devices have faced many problems in the process of removing dust from the trays that contain the devices. Until now, a rinse-type cleaner was used to remove dust from the trays, but this was recognized as a major problem because of the time and space required for the drying process after washing, the need to comply with increasingly strict regulations regarding waste cleaning solution, and the need to assign several workers to perform a series of operations was recognized as a major problem. |  |

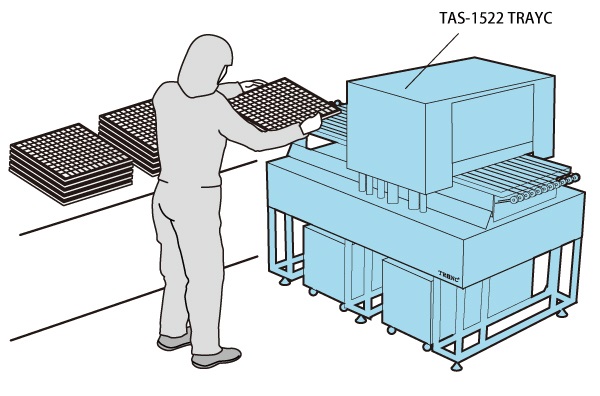

The plant successfully solved all of these problems by switching from the current water-rinse type tray cleaner to a TRINC’s TRAY CLEANER.

The system uses dense ion air blow to remove and collect foreign matter, eliminating the need for drying equipment and time, and generating no waste fluid.

In addition, the equipment automatically cleans the trays and returns them to their original locations, successfully reducing the number of workers required. In addition to these benefits, the deciding factor was the high dust removal performance, which is equal to or better than that of existing water-rinsed tray cleaners.

Since similar cleaning processes are used in many plants in Japan and overseas, TRINC’s TRAY CLEANERs will be set as the standard tray dust removal equipment and will be deployed

horizontally in the future.

The system uses dense ion air blow to remove and collect foreign matter, eliminating the need for drying equipment and time, and generating no waste fluid.

In addition, the equipment automatically cleans the trays and returns them to their original locations, successfully reducing the number of workers required. In addition to these benefits, the deciding factor was the high dust removal performance, which is equal to or better than that of existing water-rinsed tray cleaners.

Since similar cleaning processes are used in many plants in Japan and overseas, TRINC’s TRAY CLEANERs will be set as the standard tray dust removal equipment and will be deployed

horizontally in the future.