SOLUTION

Optical/precision equipment

Foreign object defects during lens assembly no longer occur at all

Case study at an industrial lens and camera manufacturer

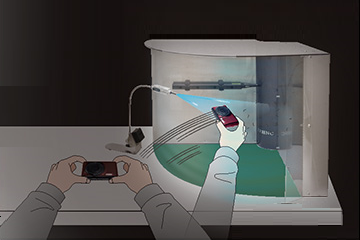

| AIR-BLOW DESKTOP TRINC (ADT), an air blow bench based on a new principle, has become indispensable as a new foreign matter control device in factories that manufacture industrial lenses and professional cameras. In the past, lenses were assembled in a general clean bench, but foreign matter adhesion was inevitable and a great deal of time and labor was wasted on rework. It was under these circumstances that the person in charge of this project discovered TRINC’s ADT and came to the TRINC Central Demo Center, hoping to find a way out of the situation. |

|

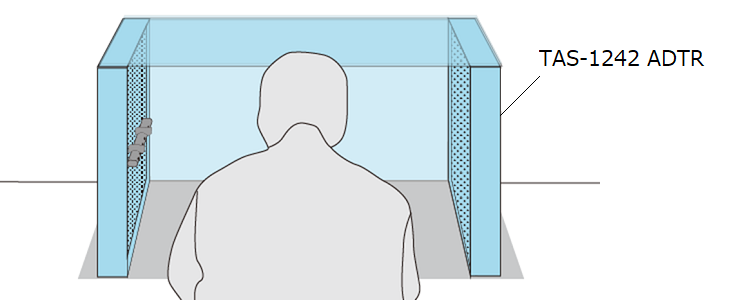

The ADT is a new clean bench that can transform a tabletop into an ideal ultra-clean environment that is class 1 and static-free, and the standard clean air blow unit can immediately remove foreign matter from products. The clean air blow unit provided as a standard feature of this new clean bench can remove foreign substances from products and immediately collect them. The clean air blow unit has a purification capacity far superior to that of conventional clean benches and prevents foreign substances

from entering the environment.

After checking at TRINC Demonstration Center, the person in charge had a gut feeling that this device was the only way, and immediately installed a unit to evaluate its effectiveness in preventing foreign matter adhesion within his company. As a result, the device proved to be more effective than expected in completely eliminating foreign matter defects in the lens unit assembly process.

from entering the environment.

After checking at TRINC Demonstration Center, the person in charge had a gut feeling that this device was the only way, and immediately installed a unit to evaluate its effectiveness in preventing foreign matter adhesion within his company. As a result, the device proved to be more effective than expected in completely eliminating foreign matter defects in the lens unit assembly process.