SOLUTION

Medical/Food/Daily Necessities

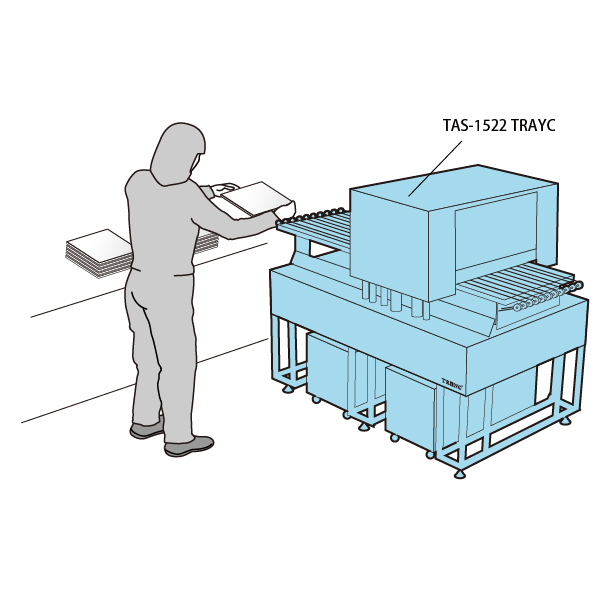

Automated cleaning of trays for medical devices that used to rely on manual labor

Case study of a tray manufacturer’s medical device tray production line

| Since medical device catheters are brought into the operating room with their trays, no foreign matter can be allowed to adhere to the trays. In this case, the catheter manufacturer strongly demanded that the trays be free of foreign matter. Therefore, several workers were assigned to the catheter tray production line to remove dust, and manual cleaning with an air blower was used. However, manual cleaning was not only time and labor consuming, but also resulted in unevenness in the work, which ultimately made it impossible to eliminate foreign matter adhesion in a targeted manner. |

|

The problem of foreign matter on catheter trays had been a long-standing problem, but the introduction of TRINC’s TRAY CLEANER quickly improved the situation. The decisive factor was its ability to consistently demonstrate high dust removal performance at all times. The cleaning process can be completed automatically and in as little as a few seconds, with quality equal to or better than manual cleaning by hand. This system is very satisfactory in terms of both elimination of foreign matter defects and labor saving.