PRODUCTS

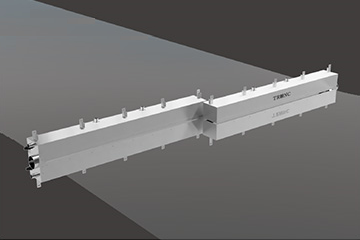

FILM TRINC

TAS-1484 FILMG-790

TAS-1485 FILMG-1590

TAS-1486 FILMG-3000

The film cleaner with a new principle featuring;

“High performance””Low cost””Retrofitable”comes on stage.

Low price

High dust-removing performance

Perfectly non-contact processing

Simultaneous operation both side

Compact size & light weight

Low power consumption

Feature details

High dust-removing performance

A cleaning rate (performance of dust-removing) is beyond largely the capability (10 to 50%) of the conventional system.

Perfectly noncontact processing

Since no roller is used, the film processed inside the system never touches anything. This prevents dust from being transferred to the film and makes the roller maintenance unnecessary.

Simultaneous operation on both sides

Both sides of the film are cleaned simultaneously in a lump. Of course, the processing only of one side is also possible.

Capable of cleaning the work (object) having an uneven surface

The cleaning head operates keeping a slight distance from the work and focusing it from different angles, so that the work even with a bit uneven surface can be cleaned. For example, the TAB tape mounted with IC chips can be cleaned.

No rollers necessary

No such a roller as used on the conventional film cleaner to restrain from behind the pressure of the air knife is required at all. So, the maintenance of rollers needed otherwise to keep the high precision job is also not required.

Compactness and lightweight

The compact and light body can be retrofitted to the old equipment without modifying it.

As a material supply mode under the recent production engineering, a case of web-materials (such as films or sheets in the form of a roll) being supplied have become more frequent because of superior productivity and efficiency, and this trend tends to be further accelerated in the future. For example, starting with the field of liquid crystal TVs, in every field like lithium ion battery, solar cell, fuel cell, flexible substrate, container for foods, medicines and cosmetics, labeling-and-packing material and printing material, those materials have started to be used. As the raw materials for them, not only plastics but copper/aluminum foils and iron are applied. However, because of the wider the surface these film and sheet have, more dust tends to adhere to them due to electrostatic action. As a result the dust adhesion problem has come under close scrutiny in every field. The method used on the conventional film cleaner to clean the dust adhering on them is such as to apply first a tension to the work (film or sheet) using rollers, next to blow off dust using an air knife and finally to remove static using ionizers. But this system has failed to get the sufficient effect in cleaning microscopic dust. To cope with this, TRINC has newly developed a basic construction and released "FILM TRINC" to solve the conventional problems.

FILM CLEANER with new principle High performance, low cost, and retrofitable