SOLUTION

Automobiles

Dust is removed at several necessary locations on the vehicle battery production line

Case study of an automotive battery manufacturing plant

| In automotive battery manufacturing plants, foreign matter attached to various materials and generated in the process must be thoroughly removed because the safety risk increases if foreign matter gets mixed inside the battery. With the numerous processes involved in battery manufacturing, the risk of foreign matter contamination exists everywhere. Conventional cleaners, however, are large and consume a lot of power, so they cannot fit into battery manufacturing facilities that are designed to be compact for automation, making it impossible to perform cleaning where it is truly needed. |

|

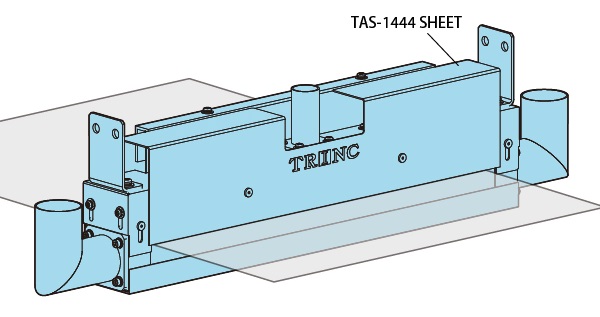

On the other hand, TRINC’s film and sheet cleaners are smaller, thinner, and more energy-efficient than other companies’ products in terms of both the cleaner head and wind power engine, so they can be installed freely within the equipment. Of course, the high dust removal capability of this specialized foreign matter and static electricity countermeasure manufacturer makes it possible to dramatically reduce the risk of foreign matter contamination.

At an automotive battery manufacturing plant, the use of TRINC’s cleaners has made it possible to significantly increase the number of cleaners initially planned, and to implement a higher level of foreign matter countermeasures.

At an automotive battery manufacturing plant, the use of TRINC’s cleaners has made it possible to significantly increase the number of cleaners initially planned, and to implement a higher level of foreign matter countermeasures.