SOLUTION

Medical/Food/Daily Necessities

100% improvement in color tone defects in cosmetic container molding

Case study at a manufacturer of plastic containers for food, cosmetics, and pharmaceuticals

| For cosmetics, the appearance of the container is an important quality item that determines the product image. Static electricity causes problems with appearance quality. The molding pellets that are used to make plastic containers are charged with a strong static electricity before being fed into the molding machine. Since different types of pellets generate different amounts of static electricity, the pellets are often mixed differently when they are actually fed into the molding machine, causing color irregularities. |

|

This case study describes improvements at a molding plant that manufactures various types of plastic containers for food, cosmetics, medical products, and other products. When molding certain cosmetic containers, as many as 50% of the containers had color irregularities, causing production to stall.

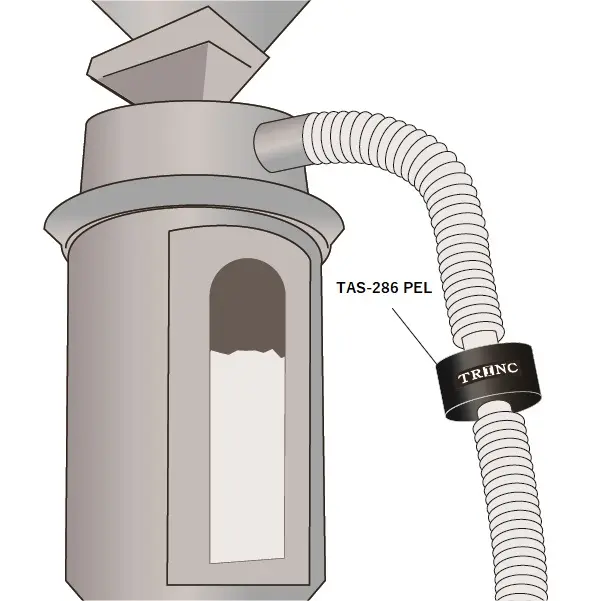

The plant introduced PELLET TRINC (TAS-286 PEL) to prevent static electricity in the pellets fed into the hopper. As a result, the surface potential of pellets fed into the hopper was reduced from 12 kV to 0.8 kV. As a result, no defects occurred at all in visual color checks, and a 100% improvement was successfully achieved.

The plant introduced PELLET TRINC (TAS-286 PEL) to prevent static electricity in the pellets fed into the hopper. As a result, the surface potential of pellets fed into the hopper was reduced from 12 kV to 0.8 kV. As a result, no defects occurred at all in visual color checks, and a 100% improvement was successfully achieved.