PRODUCTS

PELLETRINC(VACUUM TRANSPORT)

XXX=025/038/050/100

Solving static electricity problems in molding machine pellets.

Super low power consumption

Feature details

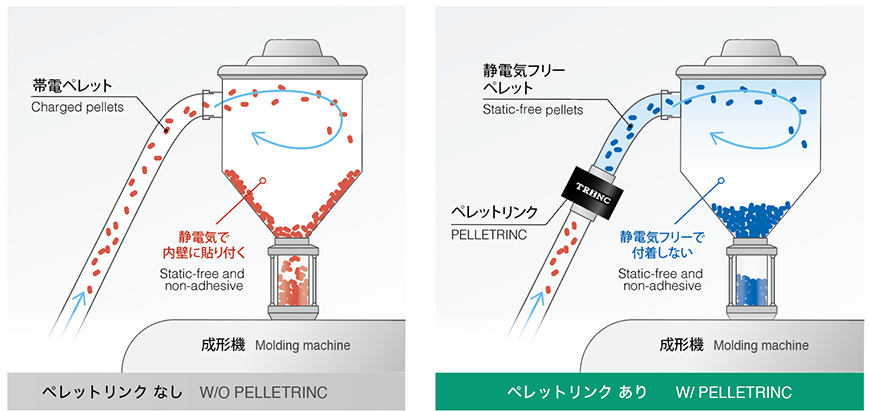

Highly concentrated ions prevent pellets from adhering to the inner wall of the hopper

Pellets stuck inside the hopper cannot be easily removed because they are firmly attracted by static electricity. As a result, it takes a lot of time to change materials, which has been a factor in lowering the operation rate of the molding machine. This machine automatically and strongly removes static electricity generated during conveyance by supplying highly concentrated ions into the hose and hopper. Pellets that have had static electricity removed will not adhere to the inner walls of the hopper. This not only drastically reduces the time required to clean up adhered pellets, but also drastically reduces the number of trials (trial runs) required for each material change, resulting in significant savings in setup time, man-hours, and materials.

Prevents uneven coloration of resin molding

Pellets and masterbatches (plastic colorants) generate different degrees of static electricity, resulting in differences in the way they adhere to the hopper wall. This machine eliminates internal static electricity, preventing all materials from adhering to the hopper wall and preventing uneven coloring caused by materials peeling off from the wall during operation.

Prevents errors in detection of material loss in molding machine hoppers

When pellets adhere to the inner wall of the hopper, the material detection sensor malfunctions. The material is at the bottom of the hopper, but the out-of-material detection signal is not emitted, preventing the material from being fed. By using this unit, the detection This prevents the machine from running out of material, especially during nighttime unmanned operation, and thus prevents major operational losses, such as machine stoppage until morning.

Electric Shock Prevention

When pellets or recycled material is sucked through the hose and transported to the hopper, a large amount of static electricity is generated inside the hose. The static electricity is so high voltage that it eventually breaks through the hose wall (discharges) and leaks onto the outside surface. This results in an electric shock the moment you touch the hose, and you receive a strong shock. This machine eliminates the large amount of static electricity generated between the pellets being transported and the inner wall of the hose, thus preventing electric shock and allowing you to work with peace of mind.

Compatible with various hose diameters

Models can be selected according to the diameter of the hose connected to the hopper. Available in 38 mm, 50 mm, and 100 mm sizes.

Low power consumption contributes to decarbonization

No air is required and no compressor is needed. Furthermore, it achieves ultra-low power consumption of only 3W, promoting decarbonization. Since air is not used, the pneumatic conveying capacity of the pellets is not reduced, and the system can be operated efficiently.

Product number (model number/format)

038

050

100