SOLUTION

Chemistry/Materials

More than doubled pellet dedusting efficiency

Case study at manufacturers of plastic parts for automobiles, home appliances, food packaging, etc.

| Pellets, which are resin molding materials, are subject to powder adhesion due to contact with equipment and pellet-to-pellet collisions during the production process. This powder causes molding defects such as surface foreign matter and black spots during the molding process, so it must be removed before being fed to the molding machine, especially when molding high quality resin parts. A powder remover is used to remove this powder, but because the pellets are swirling violently in the remover, static electricity is generated there, making it impossible to improve the powder removal efficiency. |

|

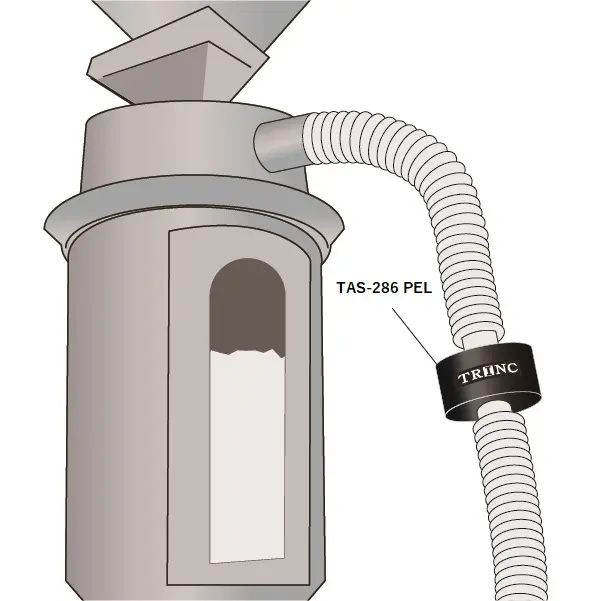

The PELLET TRINC (TAS-286 PEL) was installed in front of the winder, and static electricity was removed from the raw material and powder, increasing the removal efficiency by more than 1.5 times. The company was so surprised at the results that they decided to expand the use of the PELLET TRINC system to other plants worldwide.