SOLUTION

Medical/Food/Daily Necessities

Dramatically reduced color blurring and uneven color defects in medical resin parts

A case study of a surgical medical device manufacturer’s plant in Mexico

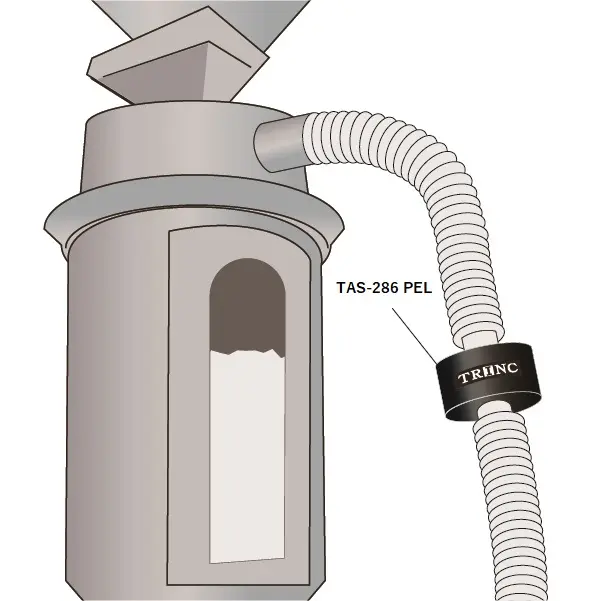

| This is an example of improvement at a factory that manufactures medical devices for surgical procedures such as cardiac and vascular surgery. Defects due to color blurring and uneven coloring were occurring in the molding process of resin parts used for products. Resin pellets, the material, become charged with static electricity while being fed through hoses, etc., and adhere to hoppers, hoses, and pipes. The degree of static electricity generated differed depending on the type of pellets, resulting in a different degree of adhesion, and as a result, the pellets fed into the molding machine were out of balance. |

|

The plant has adopted the PELLET TRINC (TAS-286 PEL-50) for its molding machines to eliminate static electricity from the supplied pellets, thereby successfully solving the problems of color blurring and unevenness in the color of resin parts.

Currently, the company is working to horizontally expand the measures to other molded parts, and is also working to prevent foreign matter by introducing air-less ionizing and space ionizing.