SOLUTION

Automobiles

Approved explosion-proof TRINC meets customer quality standards for instrument panel

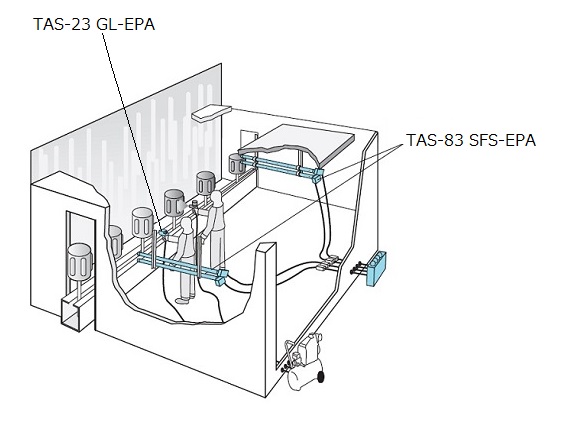

Example of a coating process at an automobile instrument panel manufacturing plant

| At an automobile instrument panel manufacturing plant, foreign matter defects in piano black paint had become a problem. A new production line was constructed, but the number of defects was so large that the factory had no choice but to appeal directly to the delivery destination to have the inspection standards leniently adjusted. Naturally, the customer strongly demanded that measures be taken to restore the inspection standards, and the company appeared to be in great distress. We checked the site and found that an explosion-proof ionizer had been installed as a countermeasure against static electricity, but it was not functioning properly because it was impossible to replace the discharge needle or perform other maintenance. Explosion-proof ionizers must be used in the correct conditions or they will not only be ineffective, but the ionizers themselves may cause ignition in the explosion-proof area, so the selection of equipment must be done carefully. |

|

After realizing the dangerous situation and the reason why foreign material defects had not been reduced, the company immediately installed TRINC’s explosion-proof ionizers (TAS-83 SFS-EPA / TAS-36 BAM-EPA / TAS-23 GL-EPA). In addition to their high ionizing capability, the explosion-proof certified TRINC ionizers, unlike other explosion-proof ionizers, are easy to clean and replace needles and easy to maintain, so they can provide high performance at any time with peace of mind.