PRODUCTS

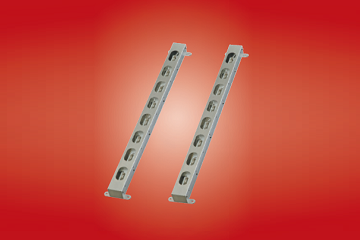

HEAT-RESISTANT STATIC-FREE SPACE TRINC(HIGH TEMP.200℃)

XXXX=250/390/530/950/1230/1510

HEAT-RESISTANT PHASED ARRAY IONIZER eliminates static electricity from high temperature workpieces like inside the drying furnace.

Air-less ionizing

Heat-resistant construction

Super low power consumption

Static-Free Space Ionizing

Feature details

Stainless steel made ion bars

The ion bars located close to work pieces for ion emission over them is made of stainless steel. Re-examining materials used for the needle holders and wiring and their structures, the ion bar is made assured of its heat resistance up to 200℃. The air-free ionizing does not require the build-in fan which lacks a heat-resistance, and contributes largely to assuring the heat -resistance as well.

Remotely controlled high voltage generating unit

The high voltage generating unit is isolated from the ion-bar. Placing the ion bar close to the work pieces which requires to be ionized and having the high voltage generating unit close at operator's hand, the system can be operated with the ion-bar alone put into the inaccessible place. The main control unit, commonly used for a bar type ionizer (Bar TRINC) and a Static-Free Space TRINC (STATIC-FREE SPACE TRINC), has a function synchronizing the polarity of neighboring ionizers with an excellent extensibility.

Air-less ionizing

This is a TRINC's unique system that diffuses ions by means of Coulomb’s repulsion. The ion-diffusion system used in ordinary ionizers emits ions towards work pieces on the air from a build-in fan or a compressor. But this air blow incurs unevenness and cooling down of temperature on the injection molding dies or high-temperature drying furnace to create a new problem. The air-free ionizing makes it possible to eliminate static without worrying about the temperature change.

Layout can be changed freely

The whole working space can be ionized thoroughly through a control of ion polarities. Making a pair of ion bars as a minimum Static-free Space TRINC unit, the space can be expanded infinitely by a combination of multiple units. By making use of the attraction and repulsion worked on both ions (positive and negative), the furnace with any complicated shape can be fil led with ions effectively.

A wall-less clean room born of TRINC's “Room-less Clean Room theory," has heaped up remarkable results in cutting off the defects resulting from static and dust in the various cases.

TRINC had given an eye to the fundamental issue of why dust adhered to work pieces and analyzed the mechanism of the dust being attracted to them. And it reached the conclusion that dust adhesion could be avoided if the whole space including the floating dust was ionized all together.

This is the concept of Static-Free Space TRINC and "High Heat-resistance type Static-Free Space TRINC" is the model to which the heat-resistance of 200°C is added. A wall-less clean room usable inside the high temperature environment, an anti-dust measure which never allow floating dust to adhere to work pieces becomes available.

Here is a Explanation of STATIC-FREE SPACE TRINC

Product number (model number/format)

390

530

950

1230

1510