SOLUTION

Automobiles

Automotive Headlamp Manufacturing Plant

Automotive headlamp manufacturer case study

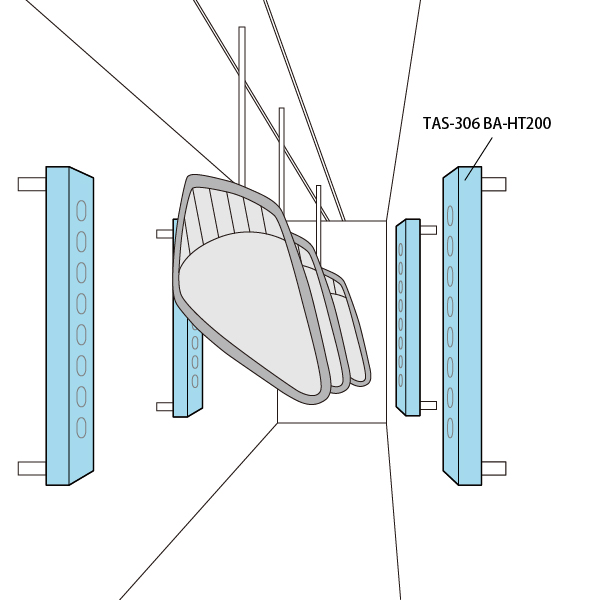

| At a headlamp manufacturing plant, foreign matter inside the unit and in the resin lens coating had become a problem. In particular, if foreign matter adhered to the lens during the coating process, it could not be easily removed afterward, so countermeasures were urgently needed. To prevent foreign matter from adhering to lenses after molding, the plant installed a BAR TRINC (TAS-311 BAM). The device is capable of powerful static elimination with no air assist, and has been very effective in preventing foreign matter from sticking to the lenses. Another deciding factor was that there was no risk of deformation due to rapid cooling of the workpiece, which is a problem with air-assisted static eliination . In addition, HEAT-RESISTANT TRINCs (TAS-804 SFS-HT200, TAS-306 BA-HT200) were installed in the furnace for drying the applied coating. This greatly reduced dust adhesion during the drying process and improved yields in the subsequent coating process. This successful example is planned to be horizontally deployed in other plants. |

|