TECHNOLOGY

Anti-Dust / -Static Measures

About “Air-less ionizing” and “Static-Free Space Ionizing”

We are introducing “Air-less ionizing” and “Static-Free Space Ionizing,” in New Standard of Anti-Dust / -Static Measures.

|

|

Air-less ionizing

|

Air-less ionizing

|

Airless ionization is indispensable for anti-foreign-material measures in the clean environment.

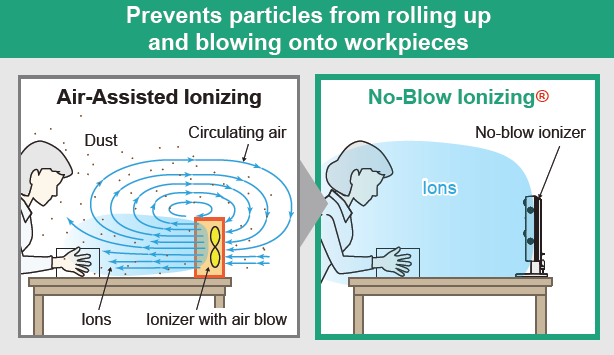

Prevents particles from rolling up and blowing onto workpieces

In the common electronics factories, ionizers those blow air to the objects to remove the static electricity have been used.

But blowing air raises the staying dust around and pollutes environment. At the same time blow-air sprays the dust to the object causing defect.

It's a mistaken stereotype that ionization cannot be done without assistance of air. It is the ions that ionization needs, and air is useless.

The static eliminator (Ionizer)of Air-less ionizing radiates only ions without using wind, keeping the environment clean and dust-free. Since dust is not blown onto the product, foreign matter defects are reduced.

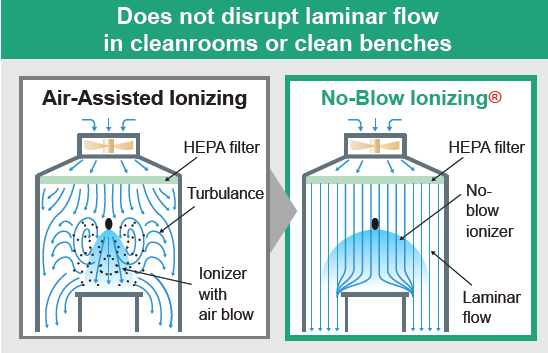

Does not disrupt laminar flow in cleanrooms or clean benches

Clean rooms and clean benches use a flow of air (laminar flow) filtered by filters to collect dust and foreign matter. However, if an ionizer that uses air blow is used in a clean room or clean bench, the flow will be disturbed, causing dust defects.

Since the static eliminator ( Ionizer ) of Air-less ionizing does not use air, dust and foreign matter do not scatter and do not disturb the original laminar flow even if it is installed in a clean room or clean bench.

Air-less ionizing is indispensable for clean rooms and clean benches to reach their full potential.

Examples of no-blow ionizer (electrostatic eliminator)

| Bar typer | High accurate bar type | EPA model | ||

TAS-311 BAM |

TAS-321 BAM |

TAS-36 BAM-EPA |

||

| Desktop | Small and spot | Handheld | ||

TAS-812 SMT |

TAS-112 SPOT |

TAS-21 GCB |

Static-Free Space Ionizing

|

|

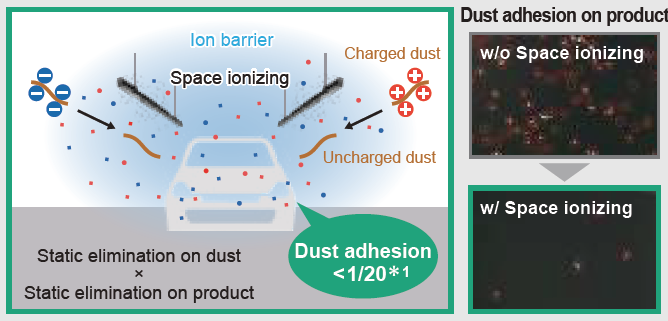

Prevents foreign matter from adhering to products

▪Highly effective for all kinds and sizes of foreign objects

▪Energy saving and lower cost than cleanrooms by far

STATIC-FREE SPACE TRINC prevents or drastically reduces dust adhesion to products by static eliminating the entire room or space, including dust floating in the space. STATIC-FREE SPACE TRINC creates an ion-filled space with no airflow.

Great results can be obtained regardless of the type of target material, such as metals, semiconductors, insulators, etc. Also, any type and size of foreign matter can be used.

Layout can be changed to suit the manufacturing site, and relocation and expansion are easy, making installation far less costly and energy-efficient than clean rooms.

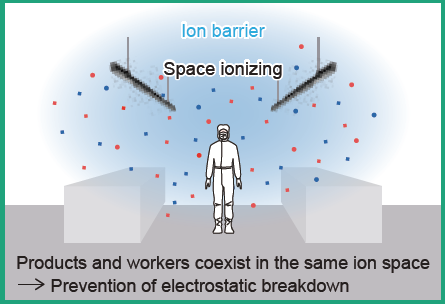

ESD countermeasure without humidification and wrist strap (ESD: Electro-Static Discharge)

▪Flexible layout and expansion

▪Higher performance, energy saving, and lowercost than humidification by far

STATIC-FREE SPACE TRINC eliminates static electricity from the worker along with the product, eliminating the need for conventional antistatic measures , such as wrist straps, conductive flooring, and conductive shoes.

The layout can be changed to suit the manufacturing site, and relocation and expansion are easy. It also has overwhelmingly better static elimination performance than humidifying the entire factory, and is low-cost and energy-efficient.

Example of Static-Free Space TRINC (Static-Free Space Ionizer)

| Standard | High accuracy model | EPA model | ||

TAS-811 SFS |

TAS-821 SFS |

TAS-83 SFS-EPA |

||

| High-temperature resistant | Desktop | |||

TAS-804 SFS-HT |

TAS-810 SMT-SFS |