TECHNOLOGY

Extraordinary improvement effect

Non-contact Film Cleaner, Web Cleaner

|

with a new method that dramatically increases the dust removal rate TRINC 's cleaner series Compact, inexpensive, non-contact dust removal on both sides Compatible with webs, films, glass, panels, metal foil, and metal plates |

Entrust the removal of dust from “WEB”, “Film”, “Panel”, “Metal film”, “Metal panel”, “Wire”, “Jig”, and “Tray” to TRINC

In recent years, film-form and panel-based materials have been used in all fields such as electronics, chemistry, automobiles, batteries, and building materials. In many cases, these films and panels should be avoided from foreign matter (dust) in terms of performance, appearance, reliability, safety, etc. As the performance of products manufactured in factories increases, stricter control over foreign matter on the material such as film or panel is required year by year. Therefore, it is necessary to ensure that foreign matter is removed before and after the various processes applied to the film.

However, until now there has been no practical device that can remove foreign matter from these film or panel with high efficiency. Also, regarding films or panels, there are various raw materials, sizes, thicknesses, widths, shapes, etc. It is not too much to say that it has been impossible to find the best cleaner for your film or panel because of its versatility.

Facing this reality, we have continued to study what TRINC, as a manufacturer specializing in static electricity and foreign matter countermeasures, should be able to do. Here, we introduce various dust removers created as a result of this research and development.

However, until now there has been no practical device that can remove foreign matter from these film or panel with high efficiency. Also, regarding films or panels, there are various raw materials, sizes, thicknesses, widths, shapes, etc. It is not too much to say that it has been impossible to find the best cleaner for your film or panel because of its versatility.

Facing this reality, we have continued to study what TRINC, as a manufacturer specializing in static electricity and foreign matter countermeasures, should be able to do. Here, we introduce various dust removers created as a result of this research and development.

TRINC’s cleaners are applicable to various materials and shapes.

TRINC's film cleaners and panel cleaners use a unique dust removal method called the "SSO method". This method can remove foreign matter from film or panels with extremely high dust removal efficiency compared to conventional cleaners. We are ahead in the world to realize a dedicated cleaner for metal foils and metal panels as well as dielectric materials such as resin, ceramics, and glass. The variety of TRINC’s cleaners has made it possible to remove dust from object with various widths, from a minimum width of 6 mm to a maximum width of 3 m.

It supports not only dust removal of roll-to-roll continuous film, but also dust removal of feeding sheets and panels. In addition, by applying the "SSO method", we have succeeded in developing a dedicated cleaner not only for flat workpieces but also for three-dimensional workpieces such as wires, jigs and trays that are often used at manufacturing sites.

It supports not only dust removal of roll-to-roll continuous film, but also dust removal of feeding sheets and panels. In addition, by applying the "SSO method", we have succeeded in developing a dedicated cleaner not only for flat workpieces but also for three-dimensional workpieces such as wires, jigs and trays that are often used at manufacturing sites.

| For wire | For narrow film | For roll-to-roll film | For roll-to-roll metal film | |||

WIRE TRINC |

FILM TRINC - MICRO |

FILM TRINC |

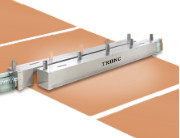

METAL FILM TRINC |

|||

| For feeding sheet | For panel | For metal panel | For ultra-narrow space | |||

ULTRA-SLIM SHEET CLEANER |

PANEL TRINC |

METAL PANEL TRINC |

FILM TRINC SLIM |

|||

| For jig or tray | ||||||

TRAY CLEANER |

Non-contact and amazing dust removal capability. Simultaneous cleaning on both sides.

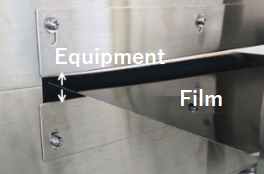

| The FILM TRINC can clean the film with non-contact on both sides. Moreover, since the distance between the device and the film is 5 mm or more on one side, setting is easy and stable performance can always be achieved. In this way, while maintaining a sufficient distance from the work, it keeps a high dust removal efficiency of 90% or more (for non-adhesive foreign matter with a size of 10um or more). |

Non-contact and amazing dust removal. |

Depending on the conditions of the work and foreign matter, 99% or more of the foreign matter can be removed.This extremely high dust removal capability is possible only by combining the efficient dust removal mechanism by TRINC's original "SSO method" and the powerful static elimination by a high-performance ionizer.

For other TRINC cleaners, the same dust removal capability and installation space between the cleaning surface and the device are secured.

For other TRINC cleaners, the same dust removal capability and installation space between the cleaning surface and the device are secured.

It is possible to install in a narrow space as many devices as necessary due to compact, lightweight, and low cost.

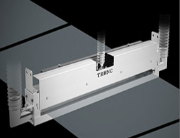

ULTRA-SLIM SHEET CLEANER

ULTRA-SLIM SHEET CLEANER, which is the world's thinnest cleaner equipped with an ionizer, the thickness of the device is only 47mm.

Compared to conventional products, TRINC cleaners are small and lightweight, and at the same time, the price is affordable. We have convictions that film cleaner should be provided as parts or units rather than large equipment for customers because it is required to be settled for each process.

We have "FILM TRINC SLIM" and "ULTRA-SLIM SHEET CLEANER" as extremely thin models. In particular, the ULTRA-SLIM SHEET CLEANER, which is the world's thinnest cleaner equipped with an ionizer, can be installed in a small gap between the equipment because the thickness of the device is only 47mm. If you have a difficulty to install a cleaner due to lack of installation space, please check TRINC’s cleaner.

We have "FILM TRINC SLIM" and "ULTRA-SLIM SHEET CLEANER" as extremely thin models. In particular, the ULTRA-SLIM SHEET CLEANER, which is the world's thinnest cleaner equipped with an ionizer, can be installed in a small gap between the equipment because the thickness of the device is only 47mm. If you have a difficulty to install a cleaner due to lack of installation space, please check TRINC’s cleaner.

| Received the Machinery and Robot Component Award in the “20th/2023 Super Monodzukuri Component Awards. |

| The Cho-Monodzukuri Innovative Parts & Components Awards, sponsored by the Monodzukuri Nippon Conference and the Nikkan Kogyo Shimbun, is an award program for outstanding parts and components that play a behind-the-scenes role in supporting Japan's manufacturing industry. TRINC's “Slim Seat Cleaner” won the Machinery and Robot Parts Award in the “20th/2023 Super Monodzukuri Parts Awards. |

Dust removal of metal foil and metal panels is possible.

Foreign matter that adheres to the metal surface due to static electricity cannot be blown off with a normal air knife, which is unavoidable physical phenomena. Therefore, there has not been practical dust remover of non-contact metal foil or metal panel cleaners.

TRINC has succeeded in developing a cleaner for metal foil and metal panel, which was impossible until now, by reviewing the mechanism of foreign matter adhesion to metal. "METAL FILM TRINC"and "METAL PANEL TRINC"were developed in this way.

TRINC has succeeded in developing a cleaner for metal foil and metal panel, which was impossible until now, by reviewing the mechanism of foreign matter adhesion to metal. "METAL FILM TRINC"and "METAL PANEL TRINC"were developed in this way.

Of course, a high-performance ionizer (electrostatic eliminator) is standard

Since this is TRINC's dust eliminator, it is of course equipped with a high-performance ionizer as standard. The use of highly concentrated ions dramatically improves dust removal efficiency. In addition, products equipped with TRINC's unique one-touch cleaning mechanism make maintenance extremely easy, as cleaning is completed in just one second without direct access to the ionizer's discharge needle.

Full range of auxiliary functions. Let us know your request.

We have experience in supporting auxiliary functions such as automatic slit opening/closing mechanisms and air ON/OFF control using external signals in response to customer requests. Please contact us if you have any auxiliary functions that you need to incorporate into your equipment.